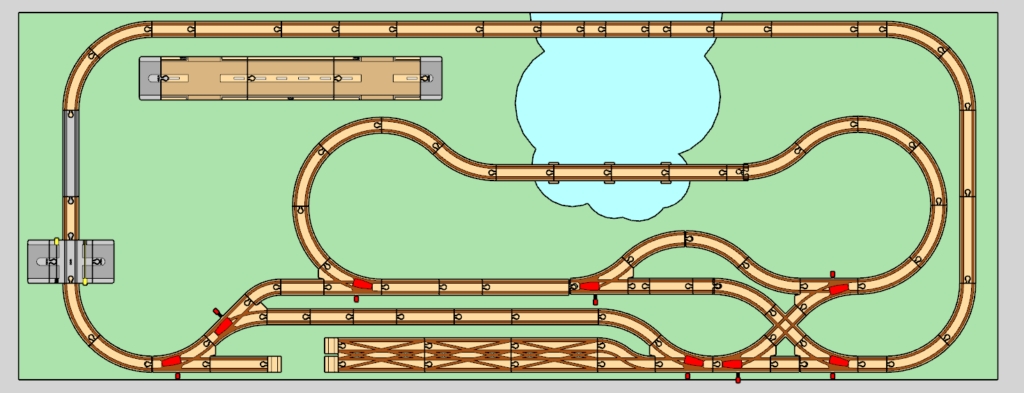

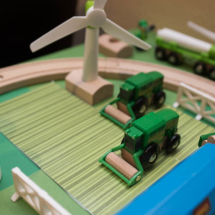

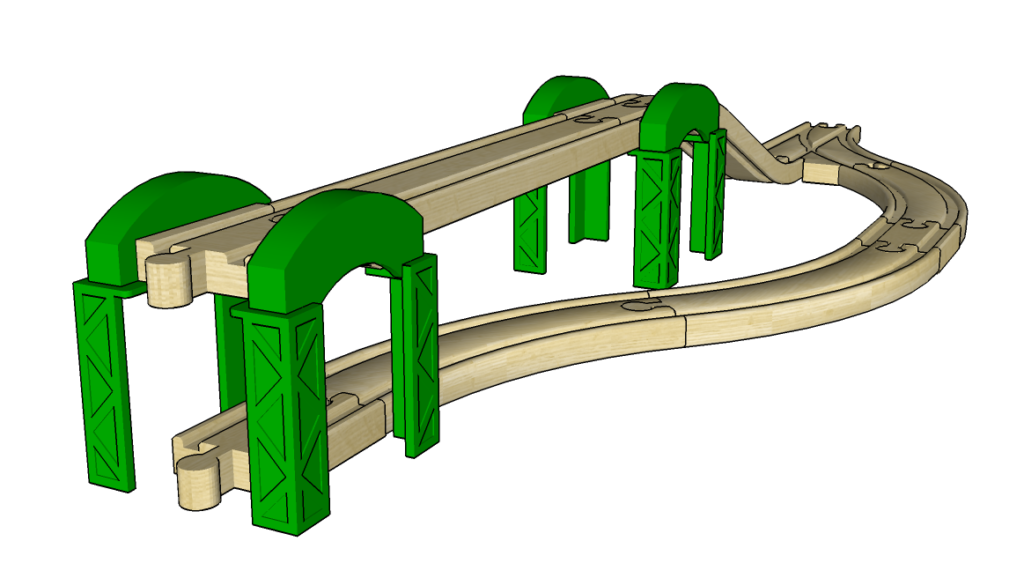

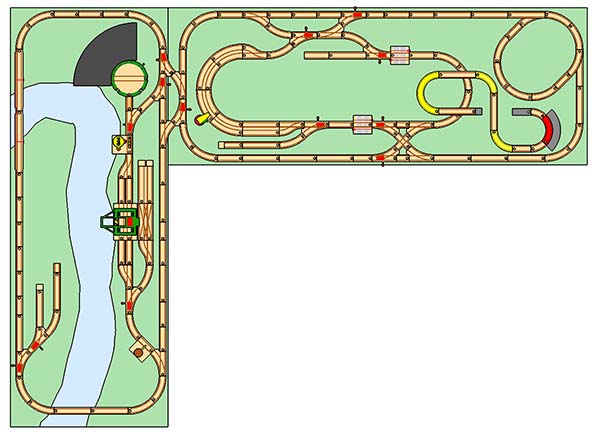

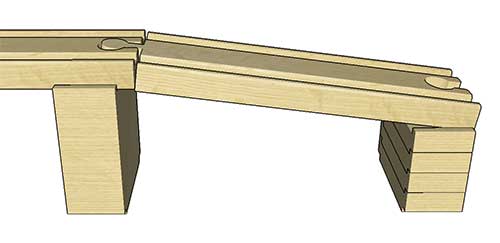

I pulled together some of my oldest pieces for this layout, which incorporates accessories from the 1960’s through the mid 1980’s. The Town set is the original version from around 1960, with double-sided printing on the buildings and a factory smokestack in red. The red lighthouses come from the second version of the Harbor Set which appeared in the mid 1970’s. Also present are two generations of the cars and trucks, the older set of which has wooden wheels (you can see the paint wear along their treads). The garage is harder to place as it was in production for well over a decade from the late 70’s through the 80’s. Similarly, the drawbridge could be from anytime between the early 60’s and the mid 70’s.

The boat is a bit of an unknown. It has similar styling to BRIO’s boats from the 1960’s and 70’s, but I’ve yet to find it in catalogs. Is it BRIO? It’s definitely beech wood, the paint finish matches BRIO parts, and it came in a lot with all genuine BRIO parts, but the possibility remains that it is from elsewhere.

The ferry shown is the 2nd generation from the late 80’s. I have the earlier model which has a solid red smokestack, but pulled out the wrong one by accident. I didn’t notice my error until after the photos were taken.